-

-

航空航天及国防行业

航空航天及国防企业正在以卓越性能为目标开发前沿的平台和系统。 政府针对全新的飞机和技术正大力推进基础设施和安全系统转型。 创新是其推动力,而在整个航空航天及国防产品生命周期和价值链中实施同步的协同式项目管理则可以促进创新。

-

-

电子和半导体行业

电子和半导体企业需要基于行业典范做法的预配置软件解决方案来实现新产品开发和推广 (NPDI) 的卓越表现。 通过缩短创新和开发周期,实现整个供应链的协作,创建闭环、智能和集成的制造环境

-

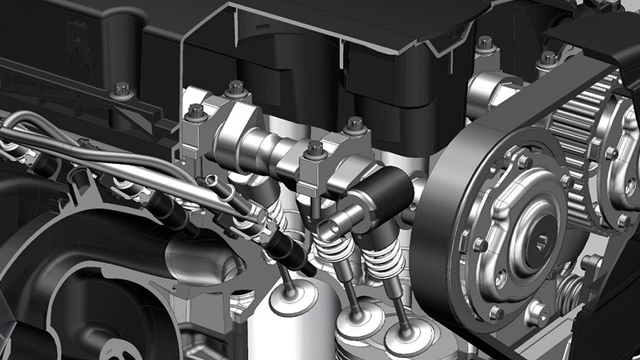

工业机械和重型装备工业

重型装备与工业机械已经具备了前所未有的复杂性。 在竞争日益激烈的市场当中,各公司不但要确保不断创新,还要应对复杂性挑战。 Siemens PLM Software 能够助您打造出适当的产品,还能让产品满足需求。

-

-

-

- NX

- Polarion

- Teamcenter

- Simcenter

- Manufacturing Operations Center

- Tecnomatix

- MindSphere

- PLM Components

-

-

-

-

-

Siemens 制造运营管理 (MOM) 软件是一套完整的解决方案,用于实施有助于制造运营实现全面数字化的战略。

Manufacturing Operation Center

-

-

MindSphere

MindSphere is the cloud-based, open IoT operating system from Siemens that connects your products, plants, systems, and machines, enabling you to harness the wealth of data generated by the Internet of Things (IoT) with advanced analytics.

-

PLM Components

PLM Components are 3D software development toolkits that increase the value of CAD, CAM, CAE and related PLM applications by reducing the time, cost and risk of delivering 3D software innovation to your customers.

-

- Mechanical Design

- Electrical & Electronics

- Software Engineering

- Simulation & Test

- Manufacturing Planning

- Factory Automation

- Manufacturing Operations Center

- Performance

-

Simcenter

Siemens NX 软件是一款既灵活又功能强大的集成式解决方案,有助于您更快更高效地提供更优质的产品。 NX 提供了下一代的设计、仿真和制造解决方案,支持公司实现数字孪生的价值。

-

-

-

-

-

-

-

-

-

Composites

|

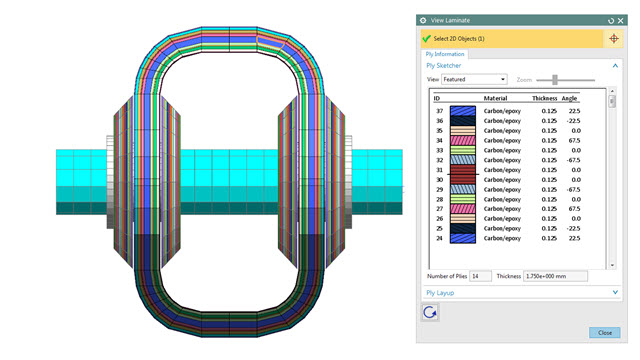

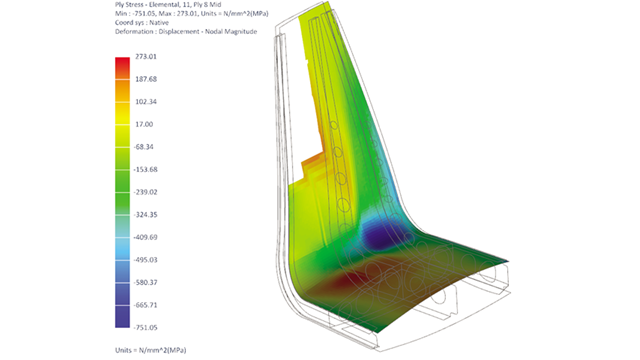

Composites

为了让产品更轻但又更结实,制造商越来越多地使用复合材料。因复合材料制成的产品构建原型的成本非常高,所以在开发采用层合复合材料的新产品时,仿真必须起到重要作用。通过不断开发材料模型和单元类型,Simcenter 在复合材料分析方面拥有领先优势。Simcenter 无缝连接复合材料设计、精确的解算器以及全面的后处理功能,大大加快仿真层合复合材料的整个过程。 |

|

Composite Solvers

Simcenter offers best-in-class solvers for speed and accuracy to compute results of your laminate composite structures. Simcenter’s solvers can analyze various performance attributes of composite structures, such as structural analysis (linear and nonlinear), thermo-mechanical simulation and acoustics. For large models, the solvers are scalable across high-performance computing (HPC) clusters to compute solutions even faster. |

|

|

|

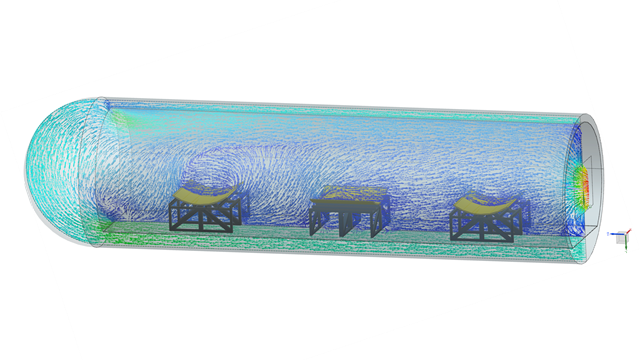

Manufacturing Process Simulation

One of the most basic problems related to the use of composite materials is the choice of a manufacturing process. This choice affects many aspects of the final component, from cost to production rate and capabilities; but also potentially has an impact on the component performance itself. Simcenter has the ability to simulate manufacturing process phenomena like curing and crystallization. Using Simcenter, you can design your composite structures to account for spring back effects and residual stresses to achieve optimal performance of your products. |

|

Pre-/postprocessing for Composites

Simcenter speeds the entire analysis modeling process for laminate composites. You can quickly create finite element properties representing your laminate composites design through integration with Siemens’ composites design software, Fibersim. Using powerful geometry editing and meshing capabilities, you can quickly create a finite element analysis model to be used with Simcenter’s solvers or for external solvers. You can then view results from these solvers directly in the Simcenter 3D environment to determine your next course of action. |

|