-

-

航空航天及国防行业

航空航天及国防企业正在以卓越性能为目标开发前沿的平台和系统。 政府针对全新的飞机和技术正大力推进基础设施和安全系统转型。 创新是其推动力,而在整个航空航天及国防产品生命周期和价值链中实施同步的协同式项目管理则可以促进创新。

-

-

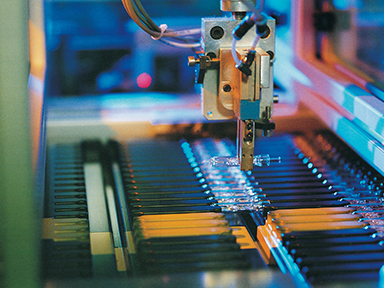

电子和半导体行业

电子和半导体企业需要基于行业典范做法的预配置软件解决方案来实现新产品开发和推广 (NPDI) 的卓越表现。 通过缩短创新和开发周期,实现整个供应链的协作,创建闭环、智能和集成的制造环境

-

工业机械和重型装备工业

重型装备与工业机械已经具备了前所未有的复杂性。 在竞争日益激烈的市场当中,各公司不但要确保不断创新,还要应对复杂性挑战。 Siemens PLM Software 能够助您打造出适当的产品,还能让产品满足需求。

-

-

-

- NX

- Polarion

- Teamcenter

- Simcenter

- Manufacturing Operations Center

- Tecnomatix

- MindSphere

- PLM Components

-

-

-

-

-

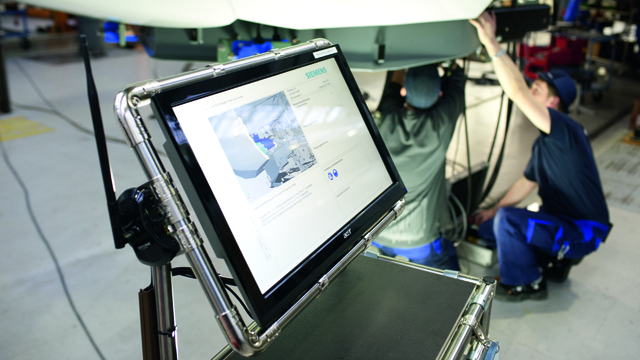

Siemens 制造运营管理 (MOM) 软件是一套完整的解决方案,用于实施有助于制造运营实现全面数字化的战略。

Manufacturing Operation Center

-

-

MindSphere

MindSphere is the cloud-based, open IoT operating system from Siemens that connects your products, plants, systems, and machines, enabling you to harness the wealth of data generated by the Internet of Things (IoT) with advanced analytics.

-

PLM Components

PLM Components are 3D software development toolkits that increase the value of CAD, CAM, CAE and related PLM applications by reducing the time, cost and risk of delivering 3D software innovation to your customers.

-

- Mechanical Design

- Electrical & Electronics

- Software Engineering

- Simulation & Test

- Manufacturing Planning

- Factory Automation

- Manufacturing Operations Center

- Performance

-

Simcenter

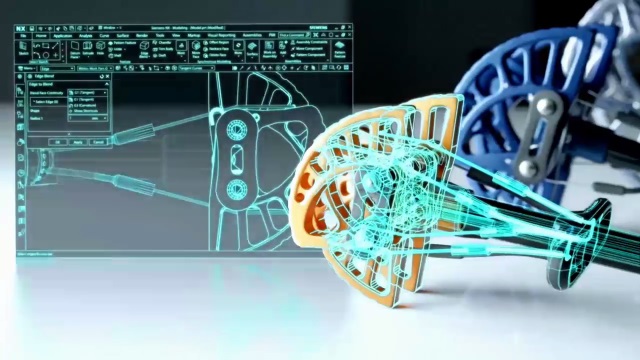

Siemens NX 软件是一款既灵活又功能强大的集成式解决方案,有助于您更快更高效地提供更优质的产品。 NX 提供了下一代的设计、仿真和制造解决方案,支持公司实现数字孪生的价值。

-

-

-

-

-

-

-

-

-

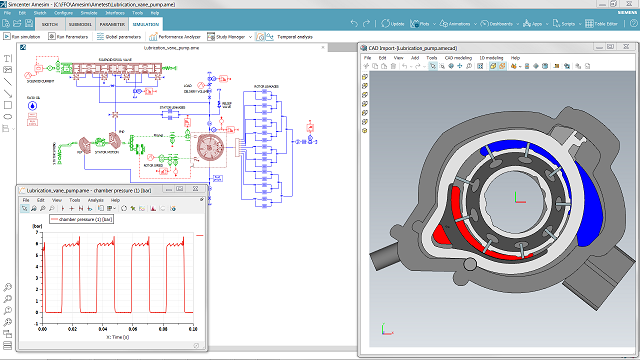

Fluid System Simulation

|

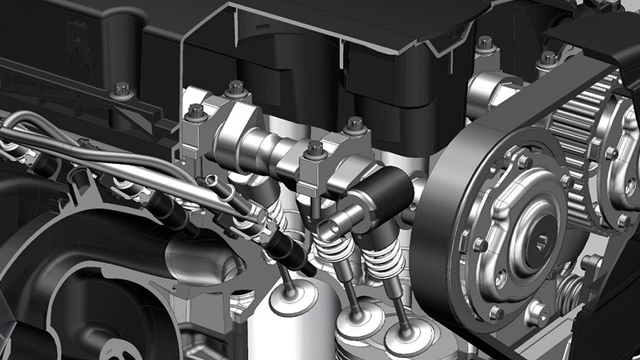

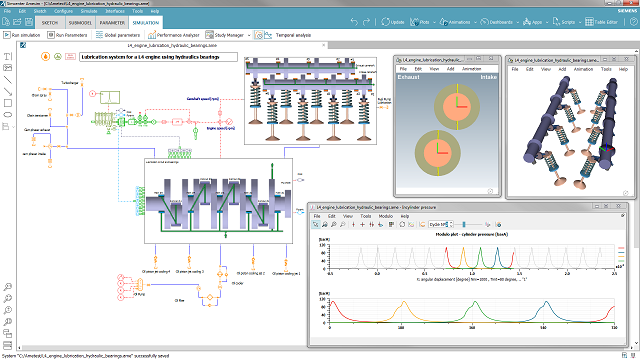

Powertrain Subsystem Simulation

加快汽门机构、曲轴系统、燃油喷射、润滑和冷却系统的设计过程。Simcenter Amesim 可用于调整组件大小,评估和优化系统效率,并验证控制策略。通过评估不同子系统之间以及子系统与燃烧室之间的相互作用,您将能够准备传动环境中子系统的集成,并分析子系统设计对发动机性能、燃油经济性或排放的影响。 |

|

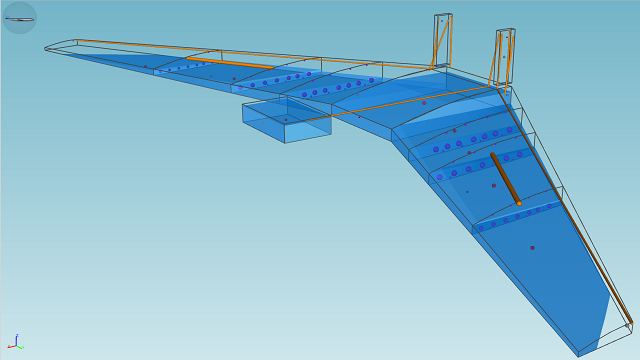

Aircraft Fuel System Simulation

Handle the challenging task of optimizing fuel pressurization, fueling, refueling and defueling of reservoirs with complex shapes while accounting for aircraft attitude, acceleration, wing bending or twisting. The software helps you model the venting, on-board inert gas generation system (OBIGGS), the fuel distribution network and the global energy management system in order to predict potential issues. You can improve efficiency, reduce weight, volume and energy consumption of your fuel systems while satisfying certification requirements. |

|

|

|

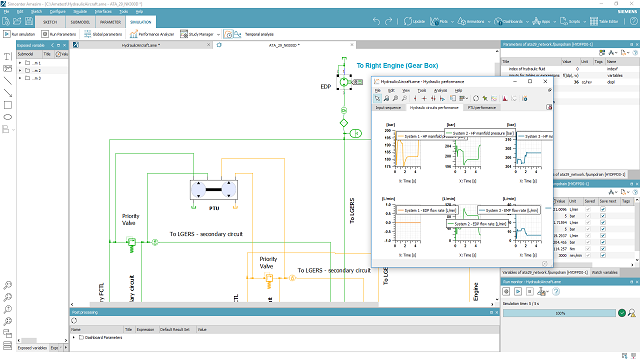

Aircraft Hydraulic System Simulation

Improve the performance of aircraft hydraulic systems by simulating their behavior for different sizing scenarios and flight missions. Simcenter Amesim provides a scalable approach to tackle engineering challenges ranging from low- to high-frequency dynamics. It allows you to integrate your hydraulic system models with those representing interfaced systems, such as electrical system, landing systems, and flight controls, to assess the aircraft performance at large. You can then estimate the system’s degraded performance by simulating how it responds to failures, and find alternative designs to meet certification requirements. |

|

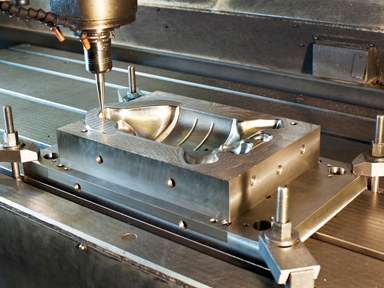

Pump and Valve System Simulation

Boost the performance of your compressors and hydraulic pumps with Simcenter Amesim. CAD import capabilities enable you to easily create a high-fidelity model from the detailed geometry. It helps you meet the increasing demand for high performance: flow characteristics, reduced pressure ripple and precise regulation of pump displacement. In addition, you can solve integration issues earlier in the design cycle, and optimize control strategies to adapt the pump flow according to the actual actuators’ request. |

|