重型装备

|

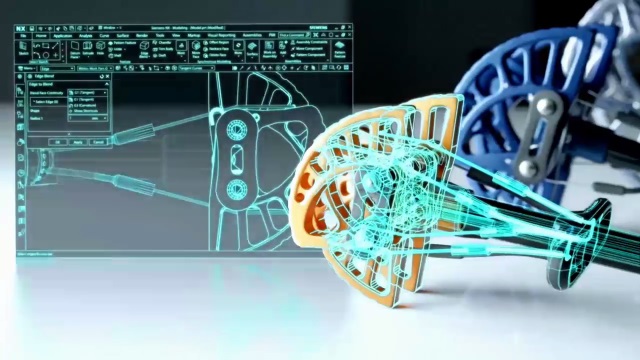

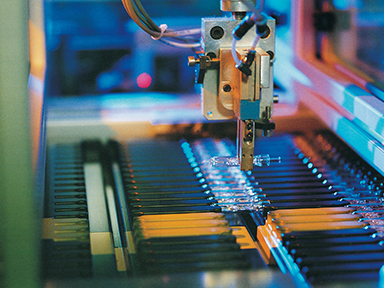

Modular Machine Engineering Process Management

Based upon module design methodology, we provide mechanisms for the engineers to systematically reuse common components, or even whole system modules, to build new machines or a complete new range of machines Our solution helps ensure an accurate configuration of the machine.This will give you confidence that the bill of material contains the right components having the right revision, and if a reused module is correctly and completely referred in the new machine design. It saves the efforts and time for the engineers to search, identify and copy the right revision of an existing module even when many changes have to be managed.New modules can also be modified from a separated copy from an existing module. Therefore, it avoids unintended changes of the existing design and the new module can be included in the machine platform for future reuse. With this mechanism, for any machine, the engineers can easily identify and track which component of which revision is used through its product lifecycle. If any change or problem is identified in the future, the impact can be easily determine. |

|

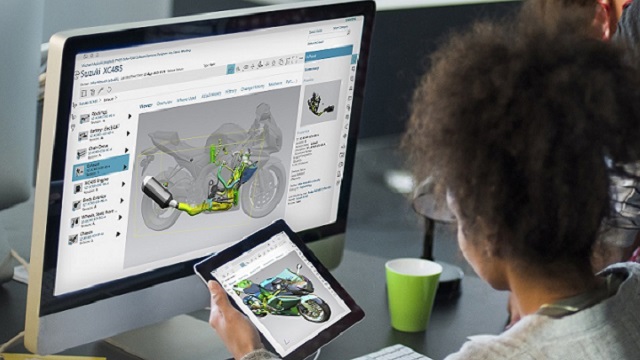

Engineer To Order Process Automation

Producing engineered to ordered machinery products can be a challenging process as they require engineering effort in both the sales proposal and order fulfillment processes. That engineering effort is time consuming, expensive, and can often be error prone given the time pressures to respond within the sales proposal and order fulfillment processes. Our solution provides a configuration backbone to support the entire machine lifecycle from product planning and engineering through manufacturing planning to execution and service. We provide robust capabilities to support customers across the spectrum of configured products. This includes Machinery customers that have product lines and models with a set of standard products with defined set of supported product variants, customers that deliver complex products with an exponential number of possible variations and combinations (Configure to Order), and customers that have highly complex and engineered to order products that require new variants of parts and designs with every order (ETO). All of these solution capabilities combine to help you deliver faster time to value, and greater solution scalability when compared to traditional approaches. |

|

|

|

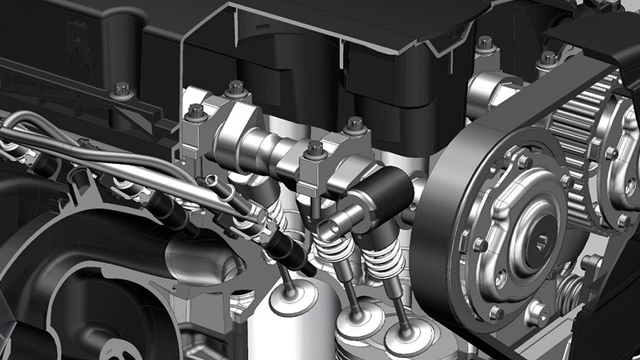

Robotics Design & Commissioning

In order for Robot builders to address the growing opportunities and challenges of complexity, globalization and quality, manufacturers need to utilize a design, simulation and manufacturing environment to plan and validate the robot design and automation aspects through the entire workflow starting from Process Definition and ending with Virtual Commissioning. |

|

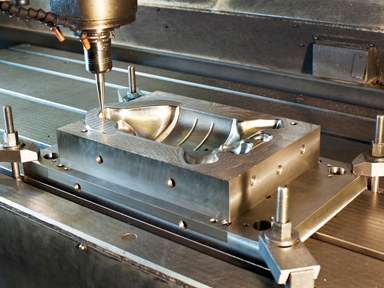

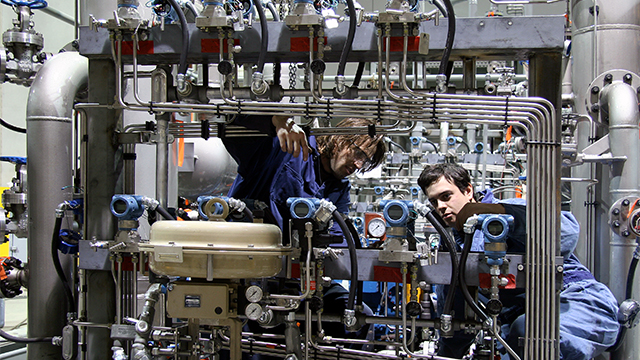

Manufacturing Process Planning & Simulation

Machinery complexity and individual customization requires multiple concurrent disciplines and flexible, modular manufacturing process plans. Historical methods are simply too time-consuming and incapable of addressing these ever-increasing challenges. Machinery developers also face a highly competitive global market that, along with machine complexity and customization, increases the risk to profitability for companies that are not able to quickly develop the most efficient use of production resources. To remain competitive in this environment, machine manufacturers must begin to digitalizing the entire manufacturing process including adding simulation during product development to minimize downtime and drive quality and cost upstream where changes cost less to implement. This can be achieved by leveraging best in class tools to communicate work flow and operating procedures to remove ambiguity and drive up first-run efficiency. Our Manufacturing Process Planning and Simulation solution for the Industrial Machinery and Heavy Equipment industry establishes a closed loop change management system between engineering and manufacturing to help both teams evaluate and assess the impact of a design change and perform assembly feasibility analyses. By establishing a controlled manufacturing change collaboration and reconciliation can help improve time to market by ensuring manufacturing and engineering are aligned and issues are identified and resolved prior to physical production. |

|

|

|

Manufacturing Process Planning & Simulation Globalization not the only hurdle machine manufacturer’s face, complexity in machine requirements and the corresponding design can also propose incredible challenges. Our lifecycle visualization tool excels where sophisticated digital mockup is used to assemble a complete digital prototype and perform advanced analysis including static and dynamic clearance analysis on the whole product and to detect issues early. Virtual Reality (VR) provides the ability to quickly navigate features from within the immersive VR environment. Manufacturers can view and analyze the 3D model at the proper scale, as well as perform typical digital mockup (DMU) operations such as sectioning, positioning, creating markups, and sharing the information with other users. The use of virtual reality systems can also be an effective tool for many parts of the organization by enabling the virtual product to be reviewed in a life-size, virtual environment with true 1:1 scale realism. Our Digital Mockup and Virtual/Augmented Reality solution can also help improve decision making by enabling you to better assess ergonomic factors such as sight lines, reachability and clearances so that you can resolve conflicts earlier. |

|

| 查看更多详情... |